Page 1 of 1

Building with guitar mold

Posted: Mon Mar 17, 2014 11:08 pm

by Steve H

Forgive me for what may be a stupid question. I've searched for previous posts but can't find my answer.

My first kit was a StewMac kit with cardboard mold. While it works adequately, I had a lot of work to get the neck set properly. OK, properly might be an exaggeration. Anyway it's close. The cardboard, in my opinion, is a weak link. The investment in the project, is too great to trust to cardboard.

I'm ready to order my next kit and I am going to invest in a guitar mold as well. I have looked for a YouTube video that answers my question and hope somebody can point me to one.

HOW DO YOU GLUE UP THE TOP USING A GUITAR MOLD AND SPOOL CLAMPS? (I can hear some of you laughing.). It can't be done with the sides in the mold and if you take it out of the mold at this point, what good is the mold? What am I missing? Video please!

Thanks

Steve

Re: Building with guitar mold

Posted: Tue Mar 18, 2014 12:14 am

by johnnparchem

Steve H wrote: ...

HOW DO YOU GLUE UP THE TOP USING A GUITAR MOLD AND SPOOL CLAMPS? (I can hear some of you laughing.). It can't be done with the sides in the mold and if you take it out of the mold at this point, what good is the mold? What am I missing? Video please!

Thanks

Steve

I would not use spool clamps with an outside mold. I only use them when I am making violins. I use cam clamps, some use the go bar deck (with a large caul).

Re: Building with guitar mold

Posted: Tue Mar 18, 2014 12:54 am

by RnB

I couldn't imagine using a cardboard mold. For the best results, a sturdy plywood mold is optimum. A body

(rimset) lives in that mold till it's closed up.

johnnparchem wrote: ...some use the go bar deck (with a large caul).

Re: Building with guitar mold

Posted: Tue Mar 18, 2014 6:54 am

by tippie53

I use bar clamps and the go bar deck. I tossed the spool clamps but I have seen them used by drilling holes in the mold. I have learned that to get the best geometry in the box , keep the sides in the mold till the top and back are on.

Re: Building with guitar mold

Posted: Tue Mar 18, 2014 7:06 am

by justrfb

Hello.

I used an outside mold and was wondering the same thing as I didn't have spool clamps and I only had a few cam clamps. What I did was this (not my idea, saw it here on another thread...) I purchased about 30 or so 1 1/2" threaded hooks from a sewing/craft store. I screwed them into the mold body about 2 - 3 " from the inside edge of the guitar outline, I bought several sets of long, flat cotton sneaker laces, tied them together to make a very long shoe lace "rope". I glued up and set the top and bottom (one side at a time), secured the mold to the bench and I strapped down the whole top and bottom (again, one at a time) in a "criss cross" pattern. Worked out perfectly. Please, as always, go through the whole process DRY (NO GLUE) the first time as practice! It may sound like an unnecessary step but please do it. It will save you from a potential big mess. I hope this is clear enough for you to imagine... I will look for a picture. Good luck!

Sincerely,

Rich

This is the thread where I got the idea... I used hooks on the top surface of the mold, he used nails into the side of the mold...

viewtopic.php?f=29&t=5610&p=27008&hilit=strap+mold#p27008

Thanks to "darren"...

Re: Building with guitar mold

Posted: Tue Mar 18, 2014 7:32 am

by JVan

I also use an outside mold, I use a combo of bar clamps, and as John had mentioned, spool clamps. I drilled holes in the mold around areas I could not reach with the bar clamps. I have not learned how to build without a mold, so I always use them, as John pointed out the "geometry" is very critical!

I like the go-bar deck for bracing, but after being beaned a few times by flying fiberglass rods, I do not like them much! lol

JV

Re: Building with guitar mold

Posted: Tue Mar 18, 2014 8:18 pm

by ruby@magpage.com

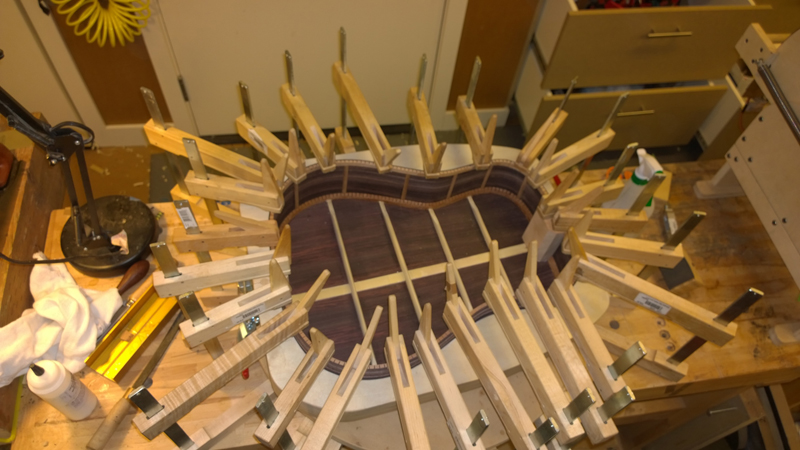

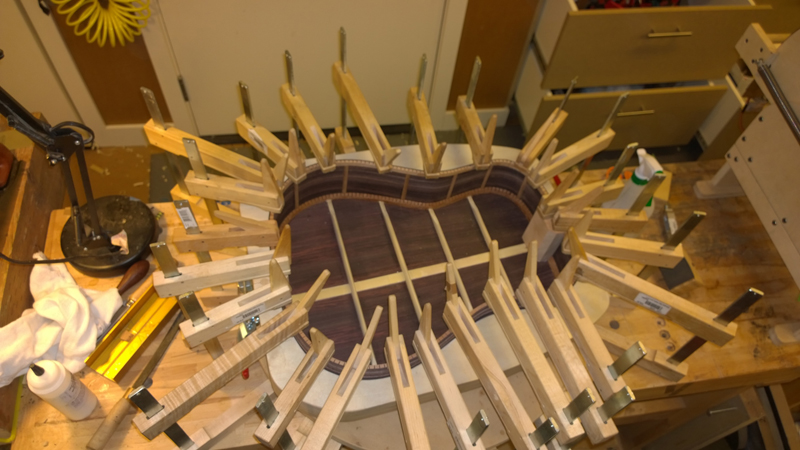

Not my idea - I make a cheap clamping caul out of 2 layers of 1/4 plywood - it is open in the middle so it does not have to bend over the dome in the back or the top. Then a clamp every couple of inches has its pressure spread out by the caul and fewer clamps are needed. I use the 8 cam clamps I have, then 2X2 or so pieces of wood with a bar clamp or a pipe clamp at either end.

Be sure to properly support the bottom of the rim with plenty of wedges to take the force of the clamps

Sorry if these are in the wrong order - the photo upload is weird and sometimes they show up backwards

Ed

Re: Building with guitar mold

Posted: Wed Mar 26, 2014 1:56 pm

by Alan Carruth

I inlet the braces of the top and back with the sides in the mold, and rout the plates to shape using a bottom bearing pattern follower. I then remove the sides from the mold to glue on the top and back. So long as the plates line up all around the edges the same way as they did in the mold, the box will come out square and not twisted: the sides were perpendicular in the mold, and that's the only way they will fit when everything lines up.

Re: Building with guitar mold

Posted: Wed Mar 26, 2014 3:56 pm

by Tom West

http://4.bp.blogspot.com/-piWdNit2K74/T ... lamped.jpg

I do it similar to this only using large elastic bands.

Tom

Re: Building with guitar mold

Posted: Fri Mar 28, 2014 12:28 pm

by JLT

I've used that system. It works well, particularly on smaller instruments like ukes and mandolins.

You can use spool clamps, though, in a way. If you put series of threaded inserts around your mold, just outside the untrimmed soundboard, you can put in a short length of all-thread into it, and use the half of the spool clamp that touches the wingnut.

The inserts look like the ones here:

http://www.woodcraft.com/Images/products/400/12J20.jpg

The picture comes from Woodcraft supply, but your local hardware store probably has something similar.