So in this thread I put the formula for NEH, along with some thoughts on projecting settle in on acoustic guitar tops. Granted, take settle in as you will. Different people say different things, some factor it, some don't. The numbers I posted are similar to what Cumpiano does on his guitars.

LINK TO NEH FORMULA: viewtopic.php?f=5&t=4983

Anyhow, here's a pictorial:

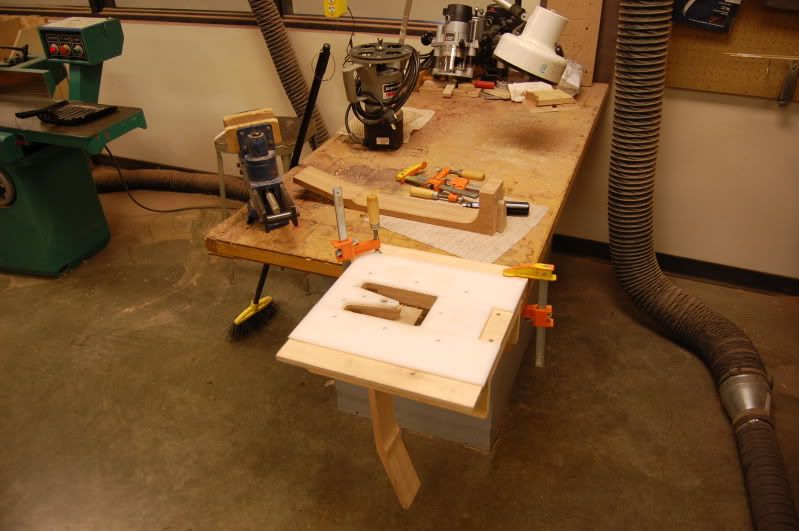

With the NEH formula, put a shim at the bridge location, and use a straight edge with sandpaper at the end to sand that angle into the body.

Use pencil for reference as to how much of the top has the correct angle into it. This picture here is pretty close to what you need. I went about half way into the pencil mark on this one. Some angles will be easy to get to the rosette. I don't let my top get top get thinner than 1/16" or so at the neck block. Also when you do this, blend the sanding into the upper bouts so you don't have trenches when you spray finish. Try to keep it smooth.

So once the angle is sanded into the top, lay a straight edge onto the top, with the shim still in place to check the ramp in the body to see how you did.

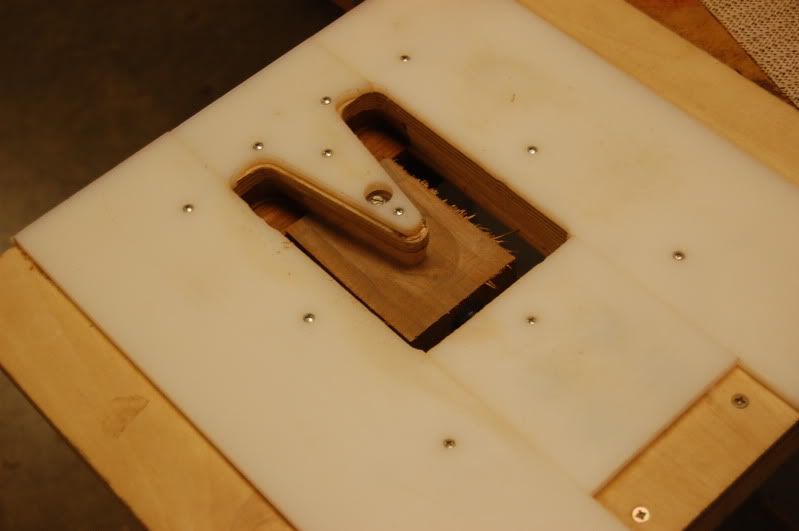

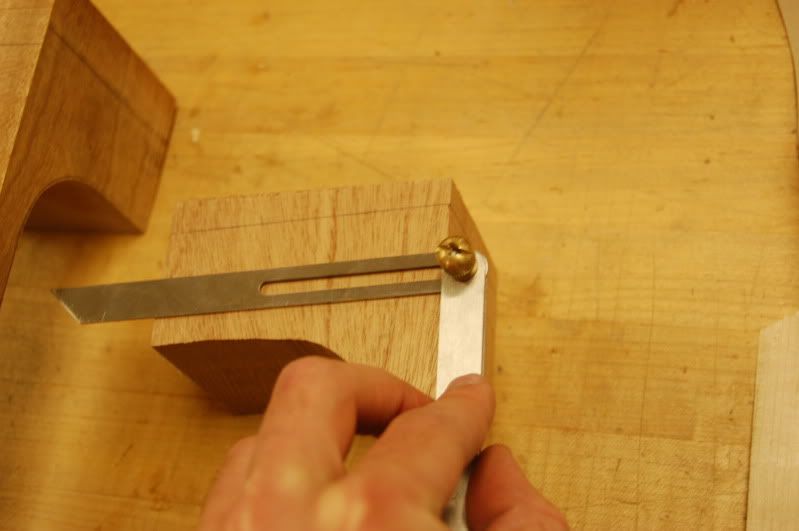

When it looks good, use gauge of some sort to copy the angle. With this tool, it's pretty straight forward. The one part lays against the straight edge, as the bottom of it gets pushed to the neck end of the body. There you have it, that's your neck angle. (BE SURE TO SAND THE NECK END VERY FLAT PRIOR TO THIS.) If you sand the neck after the fact, it could change with just adds time to the fitting process later.

Next up, take a scale length template to mark out your body joint. Lining up the nut, since this is a 14 fret to the body, I'm marking out the 14th fret.

Then use a sqaure to draw the line across. BE SURE TO ADD THE LENGTH OF THE DOVETAIL (Or tenon). If you draw a line and cut it off right on the 14th fret, your neck is firewood.

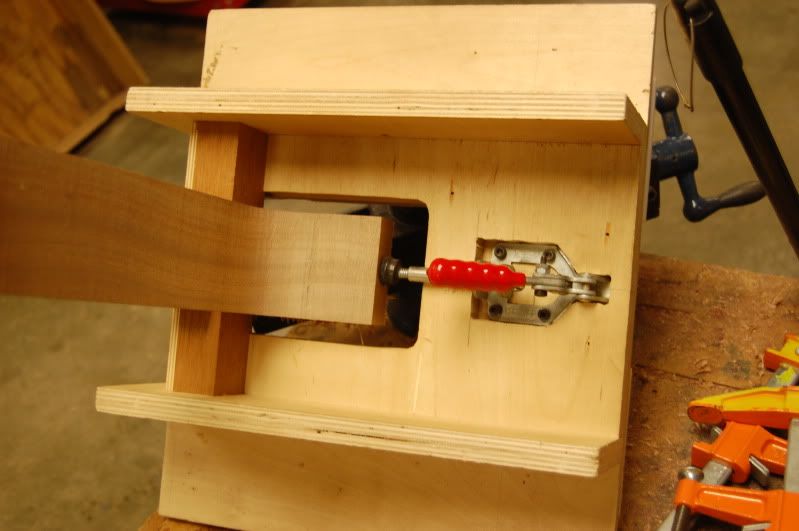

Take the gauge with your angle on it, lay it up flush to the top of your neck block, lined up with the END OF YOUR DOVETAIL (Not 14th fret line) and trace that line down. Now the neck angle is traced directly onto the neck block.

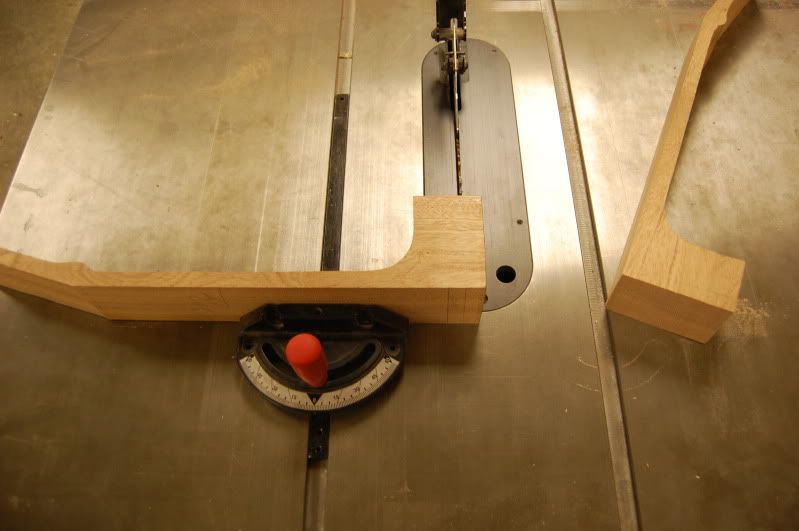

Set the miter on the table saw, or possibly a miter saw for that matter, and cut it off to that angle. I wouldn't personally use bandsaw because the blades don't seem to cut as clean for something like this, but it doesn't mean you can't.