Here is my parts list:

Qty Item

2 24x24x(5/8) Particle Board

4 36x(3/4) black pipe

1 24x24x1 MDF

4 3/4" Pipe clamp

4 3/4" flange

16 1/4" coarse thread 5/8 T-nut

16 1/4" coarse thread bolts 5/8" long

1 12" Lazy susan turntable

8 #6 machine screws 1/2"

24 48" fiberglass kite rods

96 fiberglass rod tips

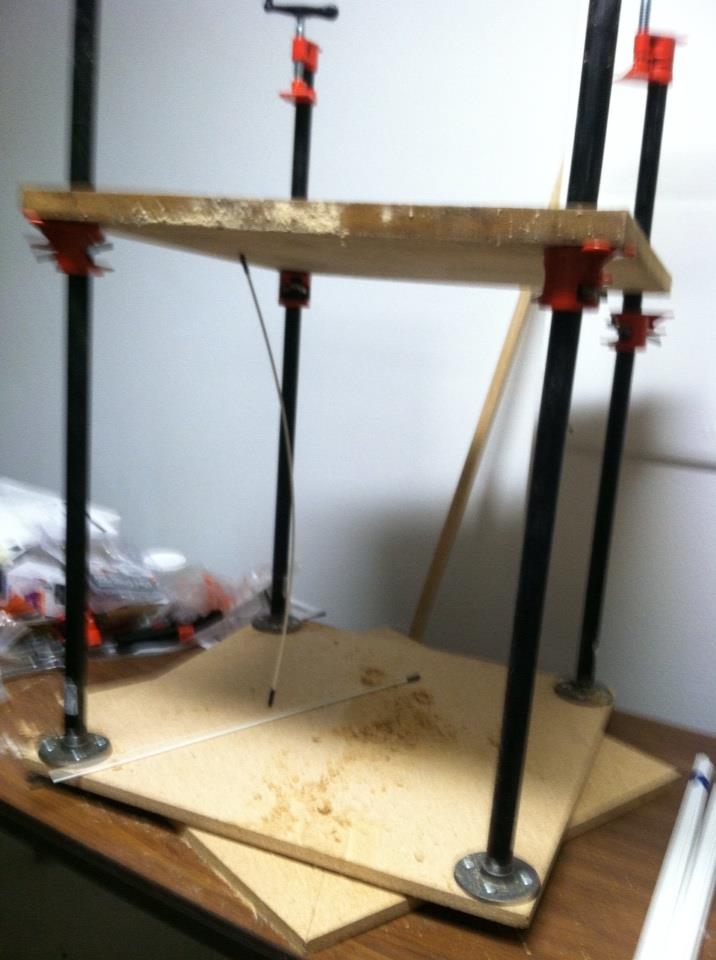

I attached the lazy susan turntable to the 5/8" particle board base using #6 machine screws

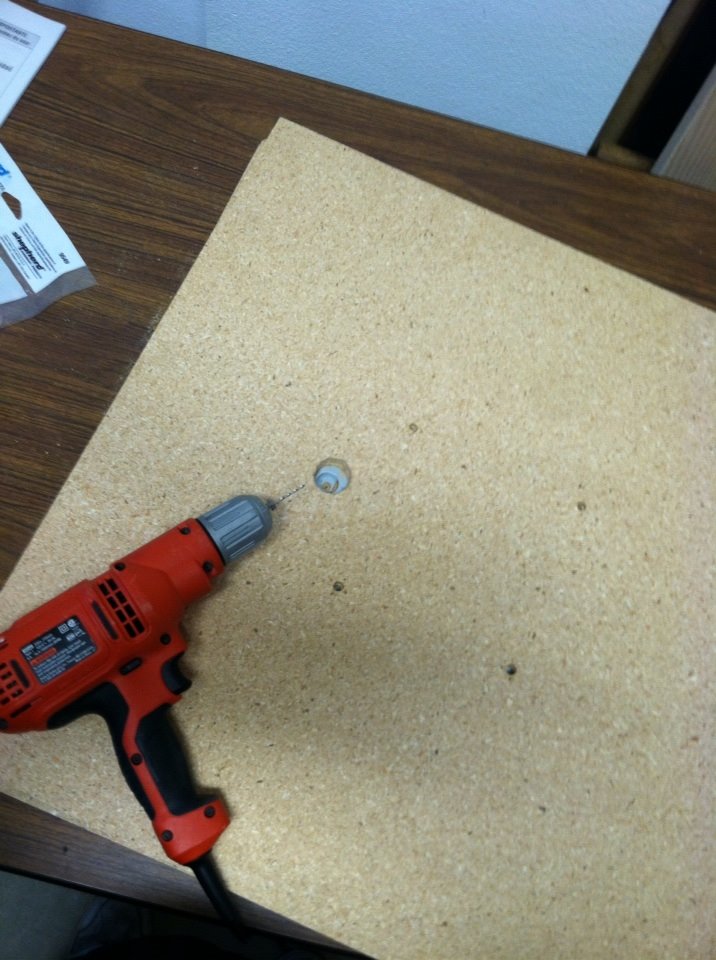

I drilled a 1.125" hole in the base so I could attach the lazy susan to the other piece of 5/8" particle board

I attached the lazy susan to the other piece of particle board using #6 machine screws which becomes the rotating board

I attached the pipe flanges to the rotating board using t-nuts and bolts

I screwed in the 36" long 3/4"pipes to the flanges

I drilled 4 holes 1.125" in diameter into the 1" MDF board which it the top of the deck

I slid a portion of a pipe clamp onto each pipe

I placed the 1" MDF board onto the pipes

I attached the other portion of the pipe clamp to the threaded section of each pipe

I cut 4 foot fiberglass kite rods using a hack saw to use as my go-bars. I put 1" caps on each end of the rods.

Here is a blurry photo of the assembled deck