Engelmann/Honduran Mahogany Dreadnought build

-

naccoachbob

- Posts: 477

- Joined: Thu Dec 03, 2009 9:25 am

- Location: Nacogdoches, Tx

Re: Engelmann/Honduran Mahogany Dreadnought build

Neil, did you leave it in the bending form for the whole 15 min with the blanket on?

My intent is to start it bending at 225, and by the time I get both bouts and the waist down, it's about 285 with this blanket. Even if I turn the temp down, it still climbs for a bit.

Thanks for the input and the comments, Neil. I'm watching yours as the FP gets better with each coat you put down.

My intent is to start it bending at 225, and by the time I get both bouts and the waist down, it's about 285 with this blanket. Even if I turn the temp down, it still climbs for a bit.

Thanks for the input and the comments, Neil. I'm watching yours as the FP gets better with each coat you put down.

-

nkwak

- Posts: 650

- Joined: Sat Nov 13, 2010 9:55 pm

- Location: Pittsburgh PA suburbs

Re: Engelmann/Honduran Mahogany Dreadnought build

The binding? IIRC I heated it up to about 300 - or maybe that was the hog sides. It's been sooo long I can't remember. What I do know is that I was playing with the EIR binding so much I noticed that it was pretty pliable - quite the opposite from your sycamore I'd wager - so the last strip I just glued to the purfling and after about a day I glued the straight strip to the body of the guitar, bending it little by little as I went. Somehow it didn't snap. Just lucky I guess.

~ Neil

-

naccoachbob

- Posts: 477

- Joined: Thu Dec 03, 2009 9:25 am

- Location: Nacogdoches, Tx

Re: Engelmann/Honduran Mahogany Dreadnought build

Neil, I think my perception that the sycamore was brittle was just because it's such a small piece thickness-wise and width-wise. I must have been like a gorilla just handling it. The bindings I'd used before were always bent to shape, and thus a bit stronger.

I'm going to have to pay a consulting fee to Tony if he ever gets wise to how much he's helping with this. His approach to bending the side purfling was to tape it to the binding pieces that I was to bend. DUH! Sheesh, I shoulda thunk of that in the first place. It worked perfectly.

I was only able to bend 2 of the purfling pieces because that's all I had. There's another batch heading to East Texas. Unfortunately they're telling me it will be next Tue before they arrive. I really hate waiting. Of course it's that desire to get moving that gets me in trouble lutherie-wise, so I'll take the hint and step back.

I'd forgotten to install these mahogany pieces along the sides to stiffen them and help against cracking. Better late than never.

I was showing a co-worker the Sycamore pieces that I got, and telling her my plans for not only the reverse side of the headstock and the tail wedge, but the rosette I had planned. Initially the rosette would only have the small circles showing, but while we were looking at it, I changed my mind and may have them transition from small to large. My plan is to have 2 pieces of sycamore, one on either side of the sound hole ( 9 o'clock and 3 o'clock. They will both be about 2-3 inches long, and arc along with some purfling. Below the sound hole at 6 o'clock, will be an ebony piece - with or without a bloodwood piece intersecting it.

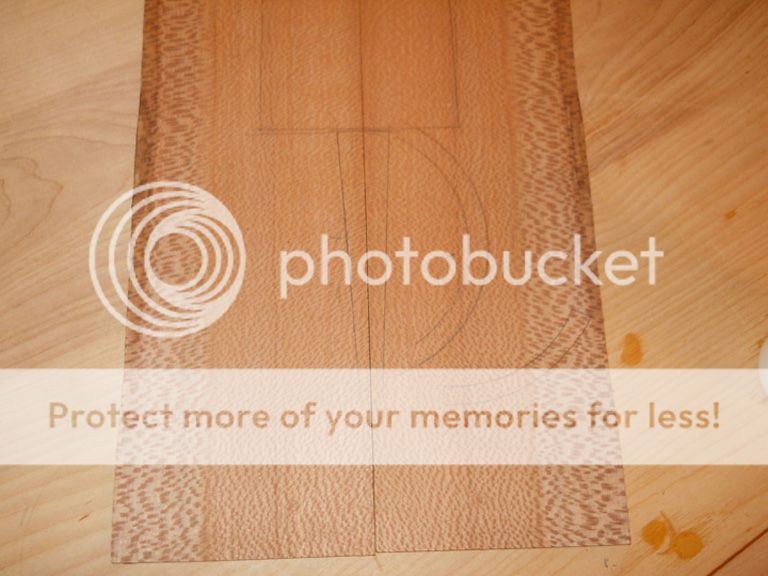

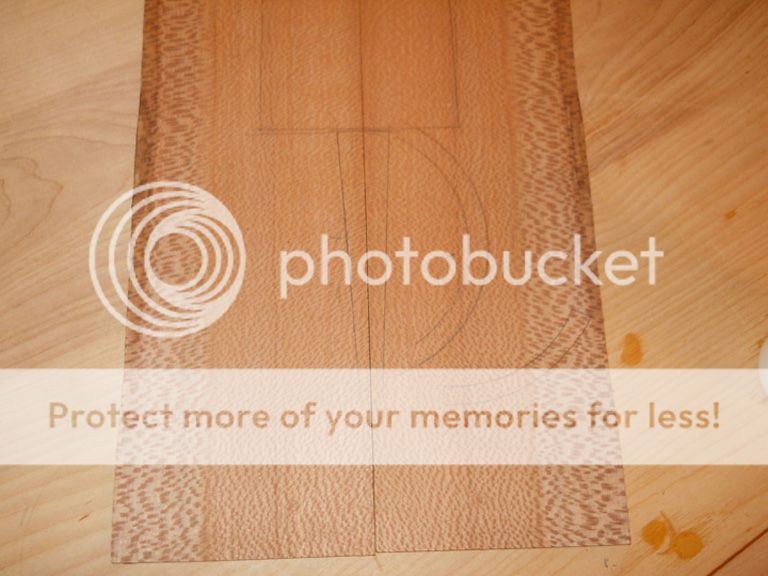

Here's the two pieces butted together. In the bottom right you can see the arc that I've drawn and that it takes in some of the larger circles/ovals/oblong things, and then transitions to the smaller ones. Above and to the left of that one, you see the other where it only has small circles in it. So my choices are: 1. transition from large to small, 2. All small, or 3. one small and one large.

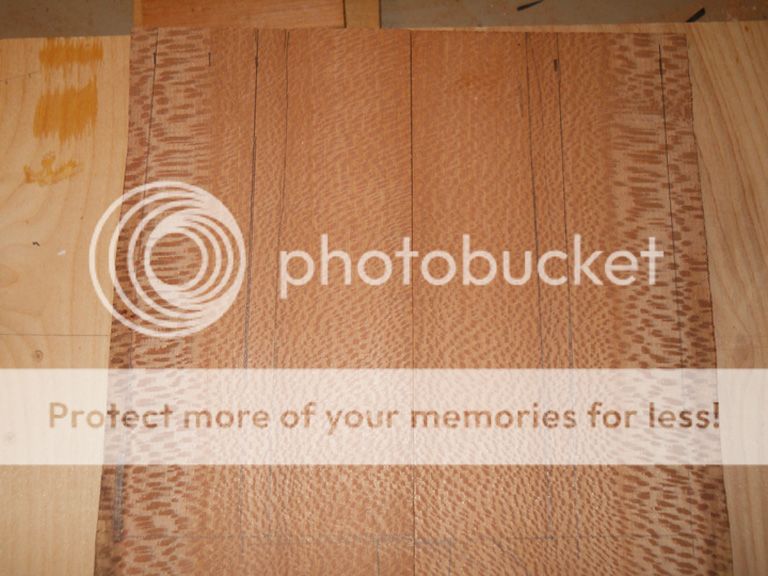

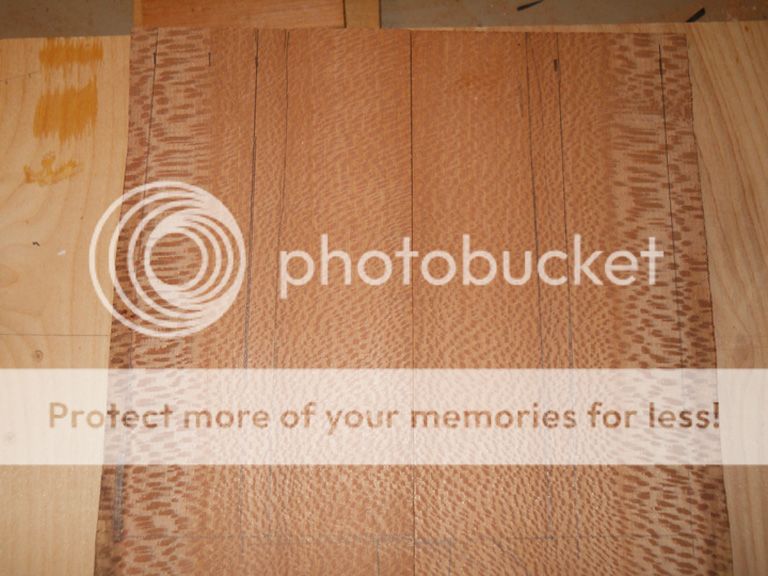

Next is the part of the 2 pieces that will make up the reverse side of my headstock. Again, my initial thought was to use the small circles, but I'm leaning a bit toward the headstock showing large circles, etc. on the edge and smaller ones on the inside. I hope you can see the lines I've drawn. In the very middle, of course, is the part with only small circles. On the outer edges I've drawn lines that have large circles on the outer 1" and 3/4" of the smaller ones. That gives the inside part 1 1/2" worth of small circles. The front side of the headstock will be ebony. I intend to curve the sides and upper end of the headstock, but final shape hasn't been decided. I'll lose some of the outer side of the sycamore by doing this.

Anyone have thoughts on this?

Thanks for looking,

Bob

I'm going to have to pay a consulting fee to Tony if he ever gets wise to how much he's helping with this. His approach to bending the side purfling was to tape it to the binding pieces that I was to bend. DUH! Sheesh, I shoulda thunk of that in the first place. It worked perfectly.

I was only able to bend 2 of the purfling pieces because that's all I had. There's another batch heading to East Texas. Unfortunately they're telling me it will be next Tue before they arrive. I really hate waiting. Of course it's that desire to get moving that gets me in trouble lutherie-wise, so I'll take the hint and step back.

I'd forgotten to install these mahogany pieces along the sides to stiffen them and help against cracking. Better late than never.

I was showing a co-worker the Sycamore pieces that I got, and telling her my plans for not only the reverse side of the headstock and the tail wedge, but the rosette I had planned. Initially the rosette would only have the small circles showing, but while we were looking at it, I changed my mind and may have them transition from small to large. My plan is to have 2 pieces of sycamore, one on either side of the sound hole ( 9 o'clock and 3 o'clock. They will both be about 2-3 inches long, and arc along with some purfling. Below the sound hole at 6 o'clock, will be an ebony piece - with or without a bloodwood piece intersecting it.

Here's the two pieces butted together. In the bottom right you can see the arc that I've drawn and that it takes in some of the larger circles/ovals/oblong things, and then transitions to the smaller ones. Above and to the left of that one, you see the other where it only has small circles in it. So my choices are: 1. transition from large to small, 2. All small, or 3. one small and one large.

Next is the part of the 2 pieces that will make up the reverse side of my headstock. Again, my initial thought was to use the small circles, but I'm leaning a bit toward the headstock showing large circles, etc. on the edge and smaller ones on the inside. I hope you can see the lines I've drawn. In the very middle, of course, is the part with only small circles. On the outer edges I've drawn lines that have large circles on the outer 1" and 3/4" of the smaller ones. That gives the inside part 1 1/2" worth of small circles. The front side of the headstock will be ebony. I intend to curve the sides and upper end of the headstock, but final shape hasn't been decided. I'll lose some of the outer side of the sycamore by doing this.

Anyone have thoughts on this?

Thanks for looking,

Bob

Last edited by naccoachbob on Fri Jul 05, 2013 5:31 pm, edited 3 times in total.

-

johnnparchem

- Posts: 2354

- Joined: Sat Apr 10, 2010 10:50 pm

- Location: Seattle

- Contact:

Re: Engelmann/Honduran Mahogany Dreadnought build

For the back of the headstock and the tail wedge I like the book matched section you have drawn so mostly small. I would like to see your idea for the rosette.

-

naccoachbob

- Posts: 477

- Joined: Thu Dec 03, 2009 9:25 am

- Location: Nacogdoches, Tx

Re: Engelmann/Honduran Mahogany Dreadnought build

John, the rosette will be a couple of pieces of the same wood used for binding and on the back of the headstock. Right now, that wood choice hasn't been made. I'm shying away from the Sycamore. I'll draw it up once I get close to what I'm seeing in my mind. But that's a little way off now.

-

naccoachbob

- Posts: 477

- Joined: Thu Dec 03, 2009 9:25 am

- Location: Nacogdoches, Tx

Re: Engelmann/Honduran Mahogany Dreadnought build

It's been a while since I made any progress on this guitar. Someone got me to thinking more about the binding, headstock, etc., that I had got the Sycamore for. It really looked so close to the Mahogany, that I didn't think it would do at all. So I ordered Cocobolo. There wasn't a doubt that it would contrast to the hog. It came in Thursday pm, and I've been messing around with using some of it and some of the Ebony on the rosette.

My initial idea was to imitate some of what Ray Kraut does on his rosettes, but I don't yet have the skills to plan or execute that kind of work. So I'll just make this one a bit unique, and a compilation of other rosettes that I've seen here and there.

In cutting the channel for this b/w/b, I used a 1/32" bit from StewMac. Unfortunately these bits come 5 or 6 to the pack for not much money. Not surprisingly, it burns the wood as it goes thru, and that's scarey in that it has to be sanded off and I just pray that there's no damage showing underneath the sanding. It turned out ok, but I'm going to invest in some carbide tipped bits that not only shouldn't burn, but should leave the surface pretty crisp.

Here are some of the pieces of Cocobolo and one piece of Ebony that will go on the rosette. I'm attaching b/w purfling around the perimeter of the Ebony in this pic. A sharp chisel makes sure the mitered joints look pretty good. To set this up, I put pins on the outside of the Ebony piece, then placed the b/w inner piece next to it, pushing pins there to hold it in. Once glued, I took out the pins for the outside of the Ebony and placed the b/w next to it and pinned that in. Just one more piece to put in. Also, the b/w imitates the binding I will do on the fret board. Since the b/w stands very proud of the Ebony, I just tacked it together with super glue. I'll install it all with LMI glue when ready to put into the rosette.

I'm about to decide what purfling to use on the Cocobolo pieces right now, so I'll sign off.

My initial idea was to imitate some of what Ray Kraut does on his rosettes, but I don't yet have the skills to plan or execute that kind of work. So I'll just make this one a bit unique, and a compilation of other rosettes that I've seen here and there.

In cutting the channel for this b/w/b, I used a 1/32" bit from StewMac. Unfortunately these bits come 5 or 6 to the pack for not much money. Not surprisingly, it burns the wood as it goes thru, and that's scarey in that it has to be sanded off and I just pray that there's no damage showing underneath the sanding. It turned out ok, but I'm going to invest in some carbide tipped bits that not only shouldn't burn, but should leave the surface pretty crisp.

Here are some of the pieces of Cocobolo and one piece of Ebony that will go on the rosette. I'm attaching b/w purfling around the perimeter of the Ebony in this pic. A sharp chisel makes sure the mitered joints look pretty good. To set this up, I put pins on the outside of the Ebony piece, then placed the b/w inner piece next to it, pushing pins there to hold it in. Once glued, I took out the pins for the outside of the Ebony and placed the b/w next to it and pinned that in. Just one more piece to put in. Also, the b/w imitates the binding I will do on the fret board. Since the b/w stands very proud of the Ebony, I just tacked it together with super glue. I'll install it all with LMI glue when ready to put into the rosette.

I'm about to decide what purfling to use on the Cocobolo pieces right now, so I'll sign off.

-

johnnparchem

- Posts: 2354

- Joined: Sat Apr 10, 2010 10:50 pm

- Location: Seattle

- Contact:

Re: Engelmann/Honduran Mahogany Dreadnought build

I am looking forward to seeing this rosette come to fruition. It really looks interesting.

-

naccoachbob

- Posts: 477

- Joined: Thu Dec 03, 2009 9:25 am

- Location: Nacogdoches, Tx

Re: Engelmann/Honduran Mahogany Dreadnought build

John, you have no idea how interesting it's got for me. I need some advice from folks here about what to do about that rosette. Right now, I have put in the 2nd set of purfling strips, and was going to rout out for the 3 pieces I made and framed.

But here's what I'm looking at.

It seems no matter what I sand with, I end up getting the dark residue all over the top. As you can see, it loads up outside the boundary of the 3 pieces I was to inlay. Also, on the left side, you can see some chip out of the spruce top that looks pretty bad.

The top is almost to final thickness now, and I'm hesitant to sand anymore for this.

What comes to mind right now is to abort this side of the top, and do this on the other side.

When you have dark purfling strips inlaid in the top, how do you avoid this?

Is this a case where I should have put some sealer on first?

All help much appreciated.

Bob

But here's what I'm looking at.

It seems no matter what I sand with, I end up getting the dark residue all over the top. As you can see, it loads up outside the boundary of the 3 pieces I was to inlay. Also, on the left side, you can see some chip out of the spruce top that looks pretty bad.

The top is almost to final thickness now, and I'm hesitant to sand anymore for this.

What comes to mind right now is to abort this side of the top, and do this on the other side.

When you have dark purfling strips inlaid in the top, how do you avoid this?

Is this a case where I should have put some sealer on first?

All help much appreciated.

Bob

-

johnnparchem

- Posts: 2354

- Joined: Sat Apr 10, 2010 10:50 pm

- Location: Seattle

- Contact:

Re: Engelmann/Honduran Mahogany Dreadnought build

Yup, use a sealer on the top. I use a blond shellac, but you can use the big box Zinsser Bullseye Shellac Seal Coat as it is wax free. But in any case stop sanding and sharpen and use a scraper or carefully use a block plan to lower the purflings.

-

Kevin Sjostrand

- Posts: 3721

- Joined: Sat Feb 09, 2008 8:06 pm

- Location: Visalia, CA

Re: Engelmann/Honduran Mahogany Dreadnought build

Bob, I'm surprised that your dust from the black fiber has been a problem. Spruce is not porous and this has never been an issue for me. I only use white glue when gluing in the fiber purflings, no sealer applied....no problem.

As far as turning that top over, you can do it, but make sure you don't cut in for your rosette in the same place, as the cuts from both sides may meet in the middle. Your outside ring looks pretty far out there anyway, so perhaps you could come in a bit and make a lesser radius, then be sure to come on either side of your existing purfling ring. Or you could change your plan a bit, rout out what you've already put in and do a different design perhaps. If you can make it happen, what you have planned looks pretty cool.

Kevin

As far as turning that top over, you can do it, but make sure you don't cut in for your rosette in the same place, as the cuts from both sides may meet in the middle. Your outside ring looks pretty far out there anyway, so perhaps you could come in a bit and make a lesser radius, then be sure to come on either side of your existing purfling ring. Or you could change your plan a bit, rout out what you've already put in and do a different design perhaps. If you can make it happen, what you have planned looks pretty cool.

Kevin