Darryl Young wrote:Looking good John!

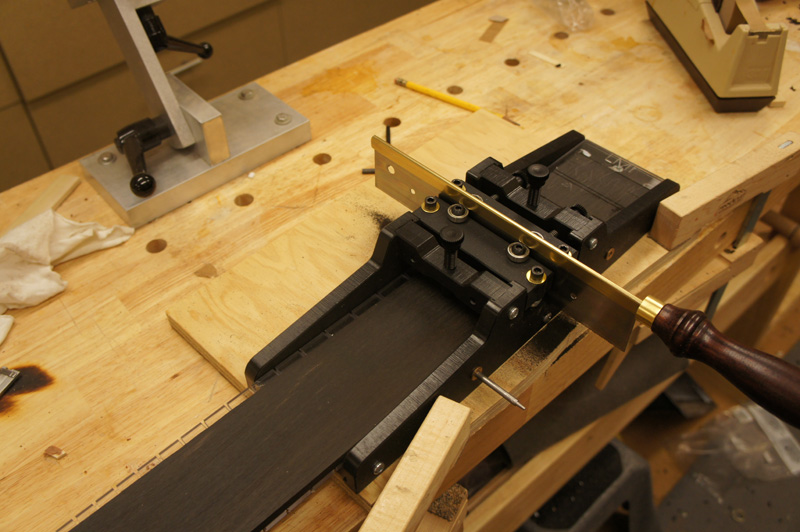

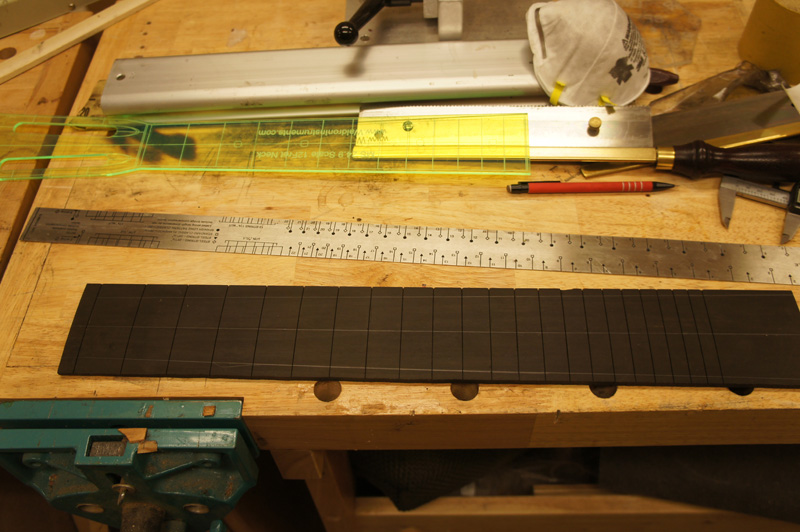

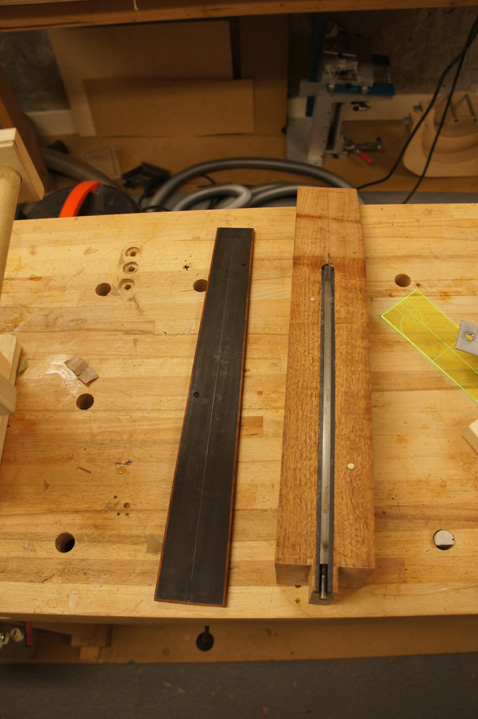

I just went to the OLF and found the thread you mentioned. After reading it, I decided to thin the AB fretboard on my 00. Took it from just shy of 0.250" down to 0.220". I'll give that a try. If I like it, I may try the 0.200" Mario mentions on the next build. I like the idea of a lighter weight neck anyhow. I also agree with the discussion over there that ebony (or at least ebony available today) is not very stable and contributes to a lot of neck movement issues. I prefer to use a rosewood for fretboards (and prefer quartersawn no matter the wood choice). Using african blackwood (AB) on this build and I have another AB blank on-hand for the next build. I would like to try Bois de Rose (sp?) as I hear it darkens to almost perfectly black over time.......but I've never found any for sale.

My experience with guitars is in the pacific northwest our relative humidity varies between about 48-65. I have not experienced any neck movement on any of my guitars. Even the cheap 100 guitars I bought for my kids.