Page 1 of 2

Inlay Issue

Posted: Sun Jan 24, 2016 10:38 pm

by Metalone72

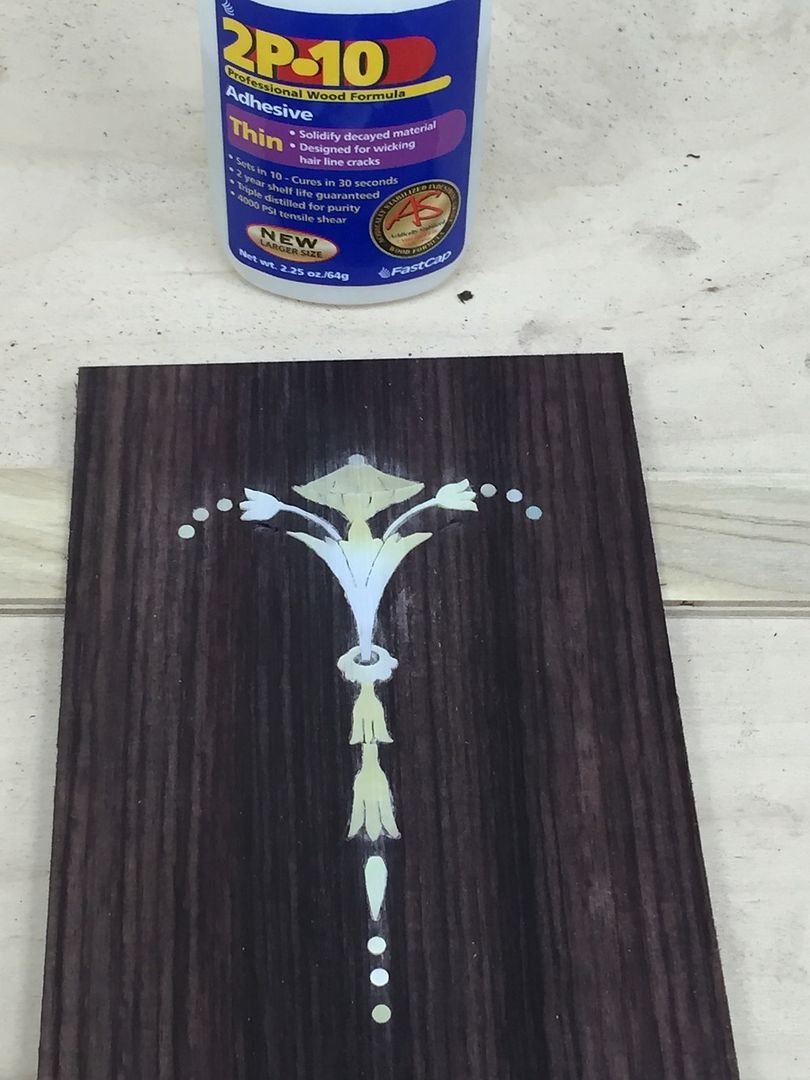

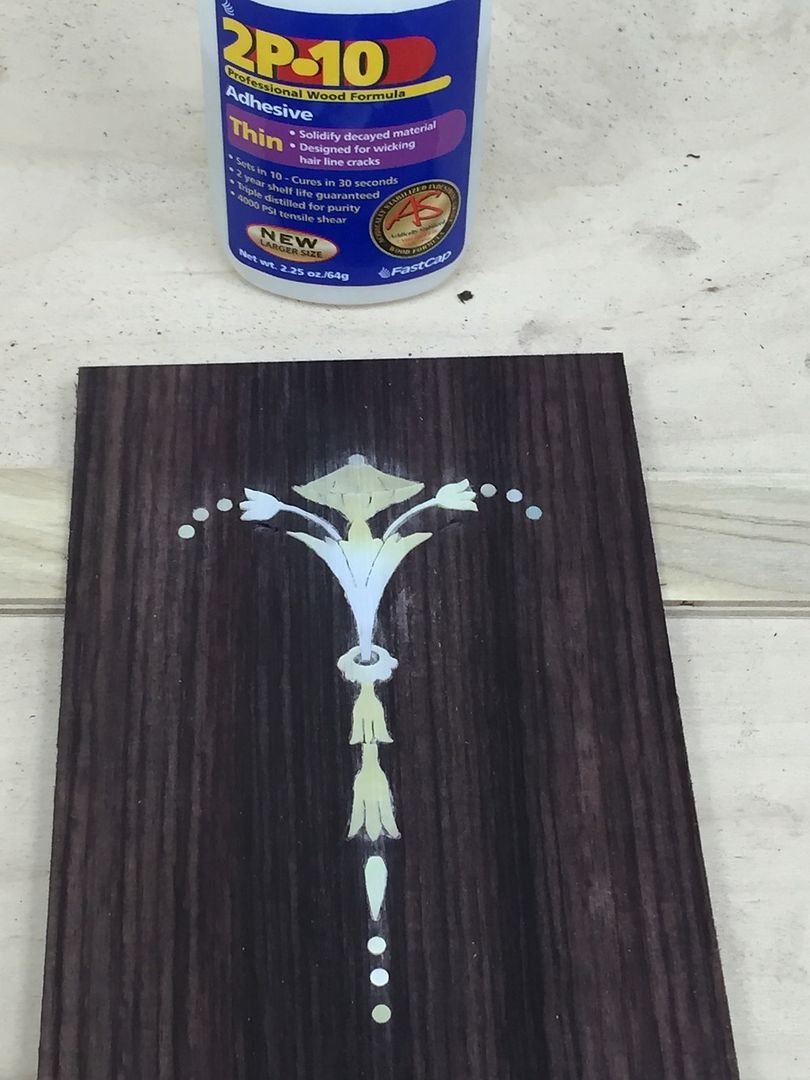

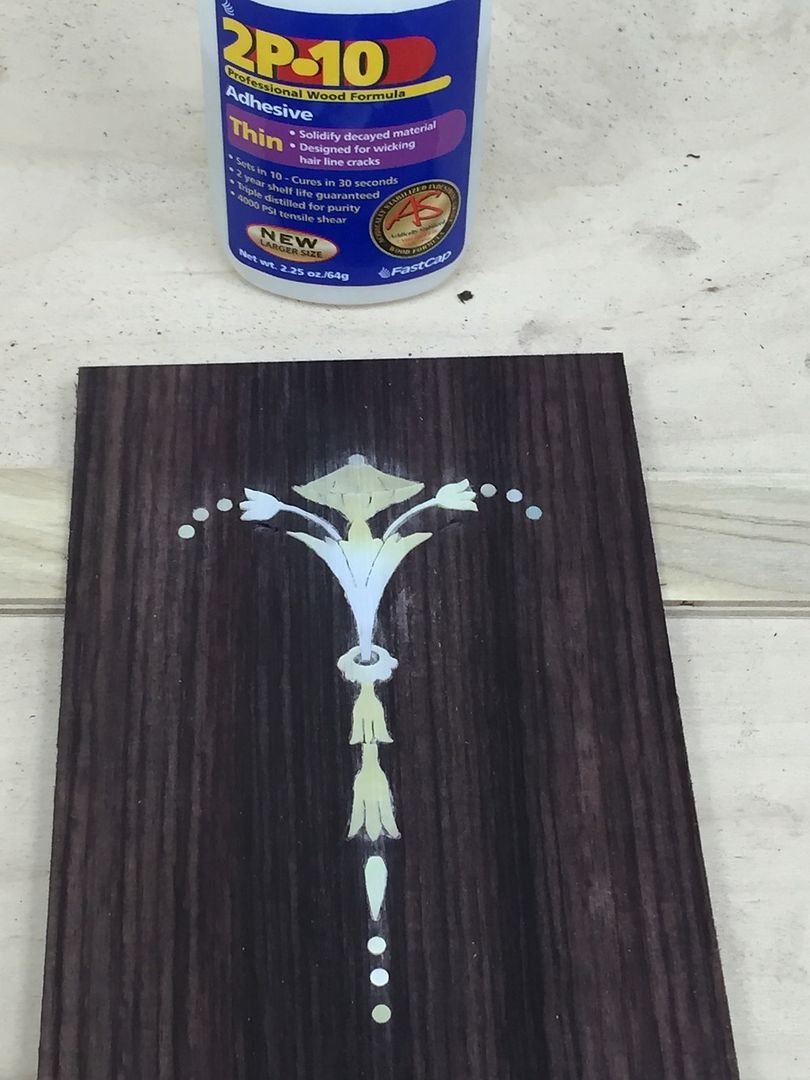

So I had some free time after shoveling out today and decided to inlay a torch headstock inlay that I cut a little while back. So I followed John's video [youtube]

http://youtu.be/o7gYBqLRdMo[/youtube]. I got the pearl inlayed and glued it as instructed. Upon sanding it through my sander one of the tear drops popped out and was lost. So as I am examining the inlay my finger catches the other tear drop and it pops out to never-never land. Further investigation revealed that a lot of the pearl is loose. I flooded it with thin super glue, let it soak in and then hit it with accelerator. I've never really used super glue to do inlay work and not sure if I really want to. Any suggestions, tips, tricks, or comments on what I am doing wrong or what I can do to rectify this. I think I am going to have to dig the pearl out of its cavities and reglue with possible putting some glue in the cavity underneath.

Thanks,

Scott

Re: Inlay Issue

Posted: Mon Jan 25, 2016 7:30 am

by tippie53

I use gold bond. CA can go bad. At this point you can take tite bond or duco and just rub it in. See if that holds it.

That or get another brand of super glue thin

I can also see a lot of gaps it may be that the super glue didn't penetrate . Try it again and see what happens.

Re: Inlay Issue

Posted: Mon Jan 25, 2016 9:44 am

by Metalone72

Thanks for the reply. The CA glue I used was about 1.5 years old so maybe that was the culprit. I'll try some fresher glue. As far as gaps, there's a few but it's not as bad as the picture suggests. That picture was taken right off the sander and the shell dust is smeared.

I also found that the up cut bits made it hard to see lines when cutting. It was a brand new bit that I used so I can assume it was sharp. I might look into some down cut bits.

Scott

Re: Inlay Issue

Posted: Mon Jan 25, 2016 10:46 am

by John J

I use ca to tack into place and then use black or tinted epoxy in the voids. Poke the epoxy into the voids to get any trapped air out. Let harden. Then sand. Works for me.

Re: Inlay Issue

Posted: Mon Jan 25, 2016 12:04 pm

by Metalone72

John, what is Gold Bond?

Re: Inlay Issue

Posted: Mon Jan 25, 2016 12:13 pm

by Diane Kauffmds

I do the same as John J and it works great for me as well.

Re: Inlay Issue

Posted: Mon Jan 25, 2016 4:59 pm

by rcnewcomb

I've had similar issues with 2P10 in non-guitar building. Either it would hold forever or the pieces would fall apart.

Re: Inlay Issue

Posted: Mon Jan 25, 2016 5:19 pm

by tippie53

StarBond

http://www.starbond.com/

not gold bond

LOL I use gold bond on my feet

Re: Inlay Issue

Posted: Mon Jan 25, 2016 6:29 pm

by phavriluk

I've used CA for building flying model aircraft for 40 years...it goes bad in the bottle. Results as described. Best to buy it in small quantities and use a newly purchased and newly opened container for any work. No use risking a project and wasting time for the few bucks a new bottle of glue costs.

Buying CA from StewMac right before you need it, or from a large mailorder hobby vendor like Tower Hobbies. And not to buy the cheapest. I've found that Pacer's products are good. Lots of other brands are vendor's labels applied to the same Bob Smith Industries products. I've had good and consistent results from the Pacer products.

And thin CA has no gap-filling qualities whatever. Any air gap means no adhesion. If I tried to say more I'd be speculating, as I've had some but very little experience with inlays.

Best to make some trial fits and learn to use the materials away from the project before committing them to the project.

Re: Inlay Issue

Posted: Mon Jan 25, 2016 6:35 pm

by Metalone72

If I filled any gaps with Rosewood powder I should be good to use the thin superglue correct?